Installing a toilet might seem like a daunting task, but with the right tools and a clear understanding of a toilet installation diagram, it becomes a manageable DIY project. A toilet installation diagram is an essential resource that outlines the specific steps, components, and measurements needed to install a toilet correctly. In this comprehensive guide, we’ll explore everything you need to know about toilet installation diagrams, including how to interpret them, the installation process, and common issues you may encounter.

What is a Toilet Installation Diagram?

Definition and Importance of a Toilet Installation Diagram

A toilet installation diagram is a detailed schematic that illustrates the various parts of a toilet and how they fit together during the installation process. This diagram is crucial because it provides a visual reference that guides you through each step of the installation, ensuring that every component is correctly placed and connected. Whether you’re a seasoned plumber or a DIY enthusiast, a toilet installation diagram is an indispensable tool that helps prevent mistakes and ensures a successful installation.

Key Components Illustrated in a Toilet Installation Diagram

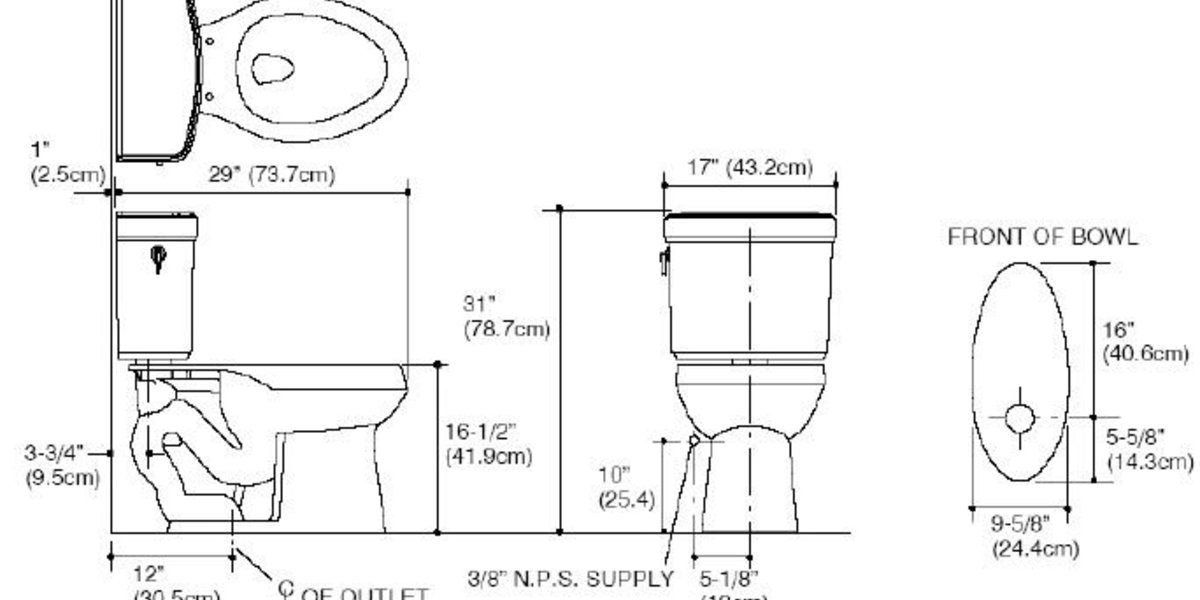

A typical toilet installation diagram will include key components such as the toilet flange, wax ring, water supply line, and trap. It will also show the rough-in measurements, which are the distances between the wall and the toilet’s mounting bolts. Understanding these components and how they interact is essential for a smooth installation. The diagram may also indicate the locations of the shutoff valve and other plumbing fixtures that need to be connected to the toilet.

How to Read and Interpret a Toilet Installation Diagram

Reading a toilet installation diagram requires some basic understanding of plumbing and construction symbols. Typically, the diagram will use arrows and labels to indicate where each component should be placed. It’s important to pay attention to measurements and alignment, as even small deviations can lead to problems like leaks or instability. Familiarizing yourself with the diagram before beginning the installation will save you time and reduce the likelihood of errors.

Preparing for Toilet Installation

Tools and Materials You’ll Need

Before you start, gather all the tools and materials required for the installation. Common tools include a wrench, screwdriver, level, measuring tape, and a putty knife. You’ll also need materials like a wax ring, toilet bolts, caulk, and possibly a new water supply line if the existing one is worn out. Having everything on hand and following the toilet installation diagram will streamline the process and prevent unnecessary trips to the hardware store.

Understanding Plumbing Codes and Requirements

Compliance with local plumbing codes is crucial when installing a toilet. These codes dictate the minimum standards for safe and effective plumbing installations, including the placement of the toilet, the height of the water supply line, and the size of the waste pipe. Before starting the installation, review the relevant plumbing codes for your area to ensure your work meets all legal requirements. The toilet installation diagram will often align with these codes, but it’s always good to double-check.

Safety Precautions Before Starting Installation

Safety should always be a priority when working on any plumbing project. Begin by turning off the water supply to the bathroom to prevent accidental flooding. Ensure that the work area is well-lit and free of obstacles. If you’re replacing an old toilet, be cautious when removing it, as older units can be heavy and cumbersome. Wearing gloves and protective eyewear is also recommended to protect yourself from debris and sharp edges.

Understanding the Rough-In Dimensions

Standard Rough-In Measurements

The rough-in measurement is the distance from the finished wall to the center of the toilet’s waste outlet (the flange). The standard rough-in size for most toilets is 12 inches, but you may also encounter toilets with 10-inch or 14-inch rough-ins. It’s important to measure this distance accurately using the toilet installation diagram to ensure that the new toilet will fit properly in the existing space. Incorrect rough-in measurements can lead to misalignment and potential installation problems.

How to Measure and Adjust for Different Toilet Models

If you’re installing a new toilet, it’s crucial to measure the rough-in dimension accurately before purchasing the unit. Use a measuring tape to find the distance from the wall to the flange bolt holes. If the rough-in doesn’t match the standard sizes, you may need to adjust the flange position or select a toilet model that accommodates your specific measurements. Refer to the toilet installation diagram for guidance on how to make these adjustments to fit the model you’ve chosen.

Common Rough-In Issues and How to Resolve Them

Sometimes, you may encounter rough-in issues during installation, such as an offset flange or an existing rough-in that doesn’t match your new toilet. These issues can be resolved by using an offset flange, which allows you to shift the toilet’s position slightly without altering the plumbing. In some cases, moving the flange might be necessary, but this can be more complex and may require professional assistance. The toilet installation diagram can help you identify the best solution for your situation.

Components of a Toilet Installation Diagram

The Role of the Flange and Wax Ring

The flange is a critical component in any toilet installation, as it connects the toilet to the waste pipe and secures it to the floor. The wax ring sits between the toilet and the flange, creating a watertight seal that prevents leaks. The toilet installation diagram will show the proper placement of the flange and wax ring, ensuring that they are aligned correctly. Installing these components properly is essential for a stable and leak-free toilet.

Importance of the Water Supply Line

The water supply line is responsible for delivering water from the shutoff valve to the toilet tank. It’s typically connected to the bottom of the tank with a flexible hose. The toilet installation diagram will illustrate where the supply line connects to the tank and the shutoff valve. Ensuring a secure connection is crucial, as a loose or improperly installed supply line can lead to leaks and water damage.

Overview of the Trap and Drain Assembly

The trap is a curved section of pipe located beneath the toilet, designed to hold water and prevent sewer gases from entering the bathroom. The drain assembly, which includes the trap, connects the toilet to the home’s waste plumbing system. The toilet installation diagram will detail the positioning of the trap and how it connects to the drainpipe. Proper installation of the trap and drain assembly is essential for effective waste removal and odor control.

Step-by-Step Guide to Installing a Toilet Using a Diagram

Positioning the Flange and Securing the Wax Ring

Begin the installation by positioning the flange over the waste pipe opening, aligning it with the bolt holes on the floor. Secure the flange to the floor using screws or bolts, ensuring it’s level and stable. Next, place the wax ring on the flange, with the tapered end facing down. The toilet installation diagram will guide you in placing these components correctly, which is critical for creating a tight seal that prevents leaks.

Placing the Toilet Bowl onto the Flange

With the wax ring in place, carefully lower the toilet bowl onto the flange, aligning the bolt holes on the base of the toilet with the bolts on the flange. Press down firmly but gently to compress the wax ring and create a secure seal. The toilet installation diagram will show you how to properly position the bowl to avoid damaging the wax ring. Once the bowl is in place, secure it with nuts and washers, tightening them evenly to prevent cracking the porcelain.

Attaching the Tank and Connecting the Water Supply

After the bowl is securely in place, it’s time to attach the tank. Position the tank on the back of the bowl, aligning the bolt holes. Insert the bolts through the holes and tighten them, being careful not to overtighten and crack the tank. Once the tank is secure, connect the water supply line to the inlet valve at the bottom of the tank. The toilet installation diagram will show the correct placement of the supply line, ensuring a watertight connection.

Connecting the Water Supply Line

Choosing the Right Water Supply Line

Selecting the right water supply line is essential for a successful installation. Flexible braided stainless steel hoses are commonly used for their durability and ease of installation. The toilet installation diagram will indicate the correct length and type of supply line needed for your toilet model. Ensure that the supply line is long enough to reach from the shutoff valve to the tank without kinking or straining.

Installing the Shutoff Valve

The shutoff valve controls the flow of water to the toilet, allowing you to turn off the water supply when needed for maintenance or repairs. The valve should be installed on the water supply pipe near the base of the toilet. The toilet installation diagram will show the proper location for the shutoff valve, ensuring easy access and reliable operation. After installing the valve, test it by turning the water on and off to check for leaks.

Testing for Leaks and Ensuring Proper Water Flow

Once the water supply line and shutoff valve are installed, it’s crucial to test the system for leaks. Turn on the water supply and allow the tank to fill. Check all connections, including the supply line and the base of the tank, for any signs of water leakage. If leaks are detected, tighten the connections or replace faulty components as needed. The toilet installation diagram can help you identify potential problem areas and ensure everything is functioning correctly.

Installing the Toilet Seat and Lid

Aligning the Seat with the Bowl

Proper alignment of the toilet seat with the bowl is important for comfort and stability. Place the seat on top of the bowl, ensuring that the mounting holes on the seat line up with the holes on the bowl. The toilet installation diagram will guide you in positioning the seat correctly, helping you avoid misalignment that can cause the seat to shift or become loose over time.

Securing the Toilet Seat with Bolts

Once the seat is properly aligned, secure it to the bowl using the provided bolts and nuts. Tighten the bolts evenly to prevent the seat from wobbling or becoming unstable. Be careful not to overtighten, as this can crack the plastic or ceramic components. The toilet installation diagram will show you the correct placement of the bolts, ensuring a secure and long-lasting installation.

Adjusting the Seat for Comfort and Stability

After securing the seat, check to make sure it is comfortable and stable. If necessary, adjust the position of the seat to ensure it sits evenly on the bowl. The toilet installation diagram may offer tips on adjusting the seat for optimal comfort and stability, which is important for daily use. Once satisfied with the position, double-check all connections and ensure that the seat remains firmly in place during use.

Sealing and Caulking Around the Base

Types of Caulking Materials Suitable for Toilets

Caulking around the base of the toilet is important for preventing water from seeping under the toilet and causing damage to the floor. Silicone caulk is commonly used for its water-resistant properties and flexibility. The toilet installation diagram will recommend the type of caulk that is best suited for your specific installation, helping you choose a product that will provide a durable seal.

How to Apply Caulk Neatly Around the Base

Applying caulk neatly requires a steady hand and some practice. Begin by cutting the tip of the caulk tube at a 45-degree angle, creating a small opening. Apply a smooth, even bead of caulk around the base of the toilet, taking care to fill any gaps between the toilet and the floor. The toilet installation diagram will show the proper placement of the caulk, ensuring that it creates a watertight seal without excess mess.

Importance of Proper Sealing to Prevent Leaks

Proper sealing around the base of the toilet is essential for preventing leaks and protecting your bathroom floor from water damage. Inadequate sealing can allow water to seep under the toilet, leading to rot, mold, and other issues. The toilet installation diagram will emphasize the importance of creating a strong, consistent seal around the entire base, ensuring that your installation is both secure and waterproof.

Troubleshooting Common Installation Issues

Fixing Wobbly or Uneven Toilets

A wobbly or uneven toilet is a common issue that can result from improper installation or an uneven floor. To fix this problem, first, check that the toilet bolts are securely tightened. If the toilet is still unstable, use shims to level the toilet, placing them under the base until it sits evenly. The toilet installation diagram will provide guidance on identifying and correcting any instability, ensuring a stable and secure installation.

Addressing Leaks at the Base

Leaks at the base of the toilet often indicate a problem with the wax ring or flange. If you notice water pooling around the base, turn off the water supply and remove the toilet to inspect the wax ring. Replace the wax ring if it appears damaged or improperly installed. The toilet installation diagram will show you how to correctly position the wax ring to prevent future leaks, helping you achieve a watertight seal.

Resolving Low Water Pressure Problems

Low water pressure in the toilet can be caused by issues such as a clogged supply line, a partially closed shutoff valve, or problems within the toilet tank. To resolve this issue, check the water supply line for obstructions and ensure that the shutoff valve is fully open. If the problem persists, inspect the fill valve and other tank components for clogs or malfunctions. The toilet installation diagram can help you identify the source of the problem and guide you in making the necessary adjustments.

Understanding Wall-Mounted Toilet Installation Diagrams

Differences Between Floor-Mounted and Wall-Mounted Toilets

Wall-mounted toilets differ from traditional floor-mounted models in that they are attached directly to the wall, with the tank concealed within the wall cavity. This design saves floor space and creates a sleek, modern look. However, the installation process is more complex and requires careful planning. The toilet installation diagram for a wall-mounted toilet will highlight the unique components and steps involved, such as the in-wall tank and carrier system.

Key Components of a Wall-Mounted Toilet Installation

The key components of a wall-mounted toilet installation include the in-wall carrier frame, the tank, the bowl, and the flush actuator. The carrier frame supports the weight of the toilet and is securely fastened to the wall studs. The tank is concealed within the wall, and the flush actuator is typically a wall-mounted button or plate. The toilet installation diagram will detail the proper placement and connection of these components, ensuring a secure and functional installation.

Steps to Properly Install a Wall-Mounted Toilet

Installing a wall-mounted toilet involves several steps, including securing the carrier frame to the wall studs, connecting the water supply and waste lines, and attaching the bowl to the carrier. The toilet installation diagram will guide you through each of these steps, emphasizing the importance of proper alignment and secure connections. Due to the complexity of this type of installation, it may be advisable to consult a professional plumber if you are unsure of any step in the process.

How to Maintain Your Toilet After Installation

Regular Maintenance Tips for Longevity

Regular maintenance is key to keeping your toilet in good working order and extending its lifespan. This includes cleaning the toilet regularly, checking the connections for leaks, and inspecting the flush mechanism for proper operation. The toilet installation diagram may provide recommendations for routine maintenance tasks, helping you keep your toilet functioning efficiently over time.

Signs Your Toilet May Need Repairs or Adjustments

Even with regular maintenance, toilets can develop issues that require repairs or adjustments. Common signs that your toilet may need attention include frequent clogs, a running toilet, or difficulty flushing. If you notice any of these issues, refer to the toilet installation diagram to identify potential causes and make the necessary repairs. Addressing problems early can prevent more serious issues and prolong the life of your toilet.

Cleaning and Care for Different Toilet Materials

Toilets are made from various materials, including porcelain, ceramic, and sometimes even stainless steel. Each material requires specific care to maintain its appearance and functionality. For example, porcelain toilets should be cleaned with non-abrasive cleaners to prevent scratching, while stainless steel toilets may require special polish to maintain their shine. The toilet installation diagram may offer cleaning tips for your specific toilet model, ensuring that you use the appropriate products and techniques.

Frequently Asked Questions About Toilet Installation Diagrams

- Why is a toilet installation diagram important?

A toilet installation diagram is essential because it provides a visual guide that helps ensure all components are correctly placed and connected, reducing the risk of errors during installation.

- Can I install a toilet without a diagram?

While it’s possible to install a toilet without a diagram, using one greatly increases the chances of a successful installation by providing clear instructions and measurements.

- What should I do if my toilet doesn’t fit the rough-in measurements?

If your toilet doesn’t fit the rough-in measurements, you may need to adjust the flange position or choose a different toilet model that matches your existing rough-in size.

- How do I know if my flange is installed correctly?

A correctly installed flange should be level with the floor and securely fastened. The toilet installation diagram can help you confirm that the flange is positioned properly before placing the toilet.

- What type of caulk should I use around the base of the toilet?

Silicone caulk is recommended for sealing around the base of the toilet due to its water-resistant properties and flexibility.

- Can I use an offset flange for my toilet installation?

Yes, an offset flange can be used to adjust the toilet’s position if the existing rough-in measurement doesn’t match the new toilet. The toilet installation diagram will guide you in using an offset flange.

- How often should I check for leaks after installation?

It’s a good idea to check for leaks immediately after installation and then periodically, especially if you notice any signs of water damage or hear unusual noises from the toilet.

- What should I do if my toilet wobbles after installation?

If your toilet wobbles, check that the bolts are tightened evenly and use shims if necessary to level the toilet. The toilet installation diagram can help you identify the correct positioning.

- Is it necessary to replace the wax ring every time I remove the toilet?

Yes, the wax ring should be replaced whenever the toilet is removed to ensure a proper seal and prevent leaks.

- Can I install a wall-mounted toilet myself?

While it’s possible to install a wall-mounted toilet yourself, it’s a complex process that may require professional assistance, especially for securing the carrier frame and connecting the in-wall components.

Conclusion

In conclusion, a toilet installation diagram is an invaluable resource for anyone looking to install a toilet, whether you’re a DIY enthusiast or a professional plumber. By following the detailed instructions and measurements provided in the diagram, you can ensure a successful installation that is both functional and long-lasting. Remember to prioritize safety, comply with plumbing codes, and perform regular maintenance to keep your toilet in optimal condition. With the right approach and tools, installing a toilet can be a straightforward and rewarding project.